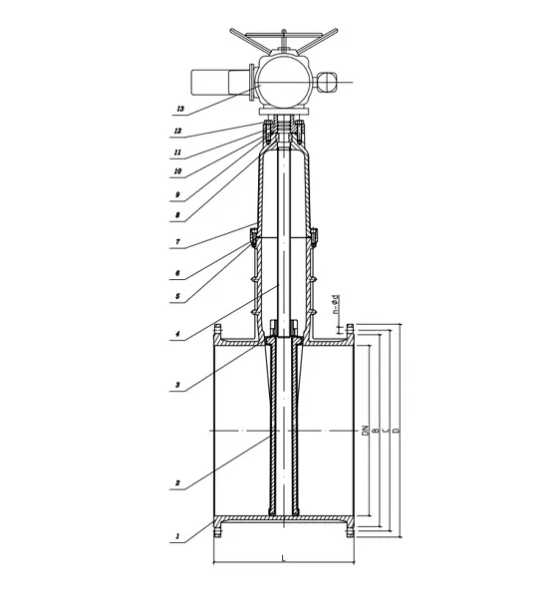

Soft Sealed Electric Gate Valve

Related recommendations : Concealed Rod Underground Spring Seat Sealing Gate Valve | Large Caliber Soft Seal Gate Valve | Magnetic Ductile Iron Elastic Seat Sealing Gate Valve

The soft sealed electric gate valve adopts a top mounted structure, which reduces the connection bolts of the valve body under high pressure and large diameter conditions, enhances the reliability of the valve, and can overcome the impact of system weight on the normal operation of the valve.

Soft sealed electric gate valves are widely used as flow separation and switching devices for medium in pipelines such as coal chemical, petrochemical, rubber, papermaking, pharmaceuticals, etc.

Nominal diameter: DN50mm~DN300mm (NPS2~12);

Nominal pressure: PN10MPa~16MPa;

Temperature range for use: -29 ℃ -300 ℃.

Part & Materials

| No | Part | Material |

| 1 | Body | Ductile Iron GGG50 |

| 2 | Wedge | Ductile Iron GGG50 +EPDM |

| 3 | Stem | SS420 |

| 4 | Stem Nut | Brass |

| 5 | Gasket | EPDM |

| 6 | Bonnet | Ductile Iron GGG50 |

| 7 | Locating Ring | Brass |

| 8 | O Ring | EPDM |

| 9 | Bolts | CS Gr 8.8 |

| 10 | Flanged | Ductile Iron GGG50 |

| 11 | Gland | Ductile Iron GGG50 |

| 12 | O Ring | EPDM |

| 13 | Bolts | CS Gr 8.8 |

Dimensions(mm)

| DN | L | D | C | B | n-d | T | f | Flange Type | W | G | K | N-d1 | S | b | h | H | Torque | Turns | |||||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||||||||||

| DN40 | 140 | 150 | 110 | 84 | 4-19 | 18 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 180 | 30 | 10 | |||||

| DN50 | 150 | 165 | 125 | 99 | 4-19 | 19 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 190 | 30 | 13 | |||||

| DN65 | 170 | 185 | 145 | 119 | 4-19 | 19 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 210 | 30 | 17 | |||||

| DN80 | 180 | 200 | 160 | 133 | 4-19 | 8-19 | 19 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 230 | 40 | 20 | ||||

| DN100 | 190 | 220 | 180 | 154 | 8-19 | 19 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 265 | 40 | 25 | |||||

| DN125 | 200 | 250 | 210 | 184 | 8-19 | 19 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 305 | 60 | 21 | |||||

| DN150 | 210 | 285 | 240 | 210 | 8-23 | 19 | 3 | F10 | 125 | 102 | 70 | 4-12 | 20 | 6 | 30 | 350 | 70 | 25 | |||||

| DN200 | 230 | 340 | 295 | 265 | 8-23 | 12-23 | 20 | 3 | F10 | 130 | 102 | 70 | 4-12 | 20 | 6 | 30 | 445 | 80 | 34 | ||||

| DN250 | 250 | 405 | 350 | 355 | 319 | 12-23 | 12-28 | 22 | 3 | F14 | 175 | 140 | 100 | 4-18 | 30 | 8 | 30 | 555 | 100 | 42 | |||

| DN300 | 270 | 460 | 400 | 410 | 370 | 12-23 | 12-28 | 24.5 | 4 | F14 | 175 | 140 | 100 | 4-18 | 30 | 8 | 30 | 615 | 120 | 50 | |||

| DN350 | 290 | 520 | 460 | 470 | 429 | 16-23 | 16-28 | 26.5 | 4 | F14 | 175 | 140 | 100 | 4-18 | 30 | 8 | 30 | 740 | 140 | 30 | |||

| DN400 | 310 | 580 | 515 | 525 | 480 | 16-28 | 16-31 | 28 | 4 | F14 | 175 | 140 | 100 | 4-18 | 30 | 8 | 30 | 820 | 160 | 34 | |||

| DN450 | 330 | 640 | 565 | 585 | 530 | 548 | 20-28 | 20-31 | 30 | 4 | F14 | 175 | 140 | 100 | 4-18 | 30 | 8 | 30 | 890 | 200 | 38 | ||

| DN500 | 350 | 670 | 715 | 620 | 650 | 582 | 609 | 20-28 | 20-34 | 26.5 | 31.5 | 4 | F16 | 210 | 165 | 130 | 4-22 | 40 | 12 | 40 | 970 | 280 | 42 |

| DN600 | 390 | 780 | 840 | 725 | 770 | 682 | 720 | 20-31 | 20-37 | 30 | 36 | 5 | F16 | 210 | 165 | 130 | 4-22 | 40 | 12 | 40 | 1150 | 290 | 50 |

| DN700 | 430 | 895 | 910 | 840 | 840 | 794 | 24-31 | 24-37 | 32.5 | 39.5 | 5 | F16 | 210 | 165 | 130 | 4-22 | 40 | 12 | 40 | 1380 | 400 | 35 | |

| DN800 | 470 | 1015 | 1025 | 950 | 950 | 901 | 24-34 | 24-40 | 35 | 43 | 5 | F16 | 210 | 165 | 130 | 4-22 | 40 | 12 | 40 | 1555 | 420 | 40 | |

| DN900 | 510 | 1115 | 1125 | 1050 | 1050 | 1001 | 28-34 | 28-40 | 37.5 | 46.5 | 5 | F25 | 300 | 254 | 200 | 8-18 | 50 | 14 | 50 | 1735 | 480 | 45 | |

| DN1000 | 550 | 1230 | 1255 | 1160 | 1170 | 1112 | 28-37 | 28-43 | 40 | 50 | 5 | F25 | 300 | 254 | 200 | 8-18 | 50 | 14 | 50 | 1910 | 550 | 55 | |

| DN1200 | 630 | 1455 | 1485 | 1380 | 1390 | 1328 | 32-40 | 32-49 | 45 | 57 | 5 | F25 | 300 | 254 | 200 | 8-18 | 50 | 14 | 50 | 2220 | 600 | 60 | |

Technical Data

| No | Description | Specification |

| 1 | Nominal Dia | DN40-DN600 |

| 2 | Nominal Pressure | PN10&PN16 |

| 3 | Valve Design Standard | DIN3352 F4 |

| 4 | Face to Face Standard | EN558&ISO5752 Series-14 |

| 5 | Flange Standard Conformity | DIN2533 |

| 6 | Testing Standard | DIN3230 |

| 7 | Expoxy Coating | Epoxy powder coating with minimum thickness of 250 microns inside and outside. |

| 8 | Testing Pressure | |

| Shell Test | PN*1.5Times | |

| Sealing Test | PN*1.1Times | |

| 9 | Working Temperature(Max) | 120℃ |