Swing Check Valve

Related recommendations : Rubber Disc Check Valve | Micro Resistance Slow Closing Butterfly Check Valve | Foot Valve

CONTACT

Product details

A swing check valve, also known as a one-way valve or check valve, is designed to prevent the backflow of medium in the pipeline. The valve that relies on the flow and force of the medium to open or close itself, in order to prevent the backflow of the medium, is called a check valve. Check valves belong to the automatic valve category and are mainly used in pipelines with unidirectional flow of medium. They only allow medium to flow in one direction to prevent accidents. This type of valve should generally be installed horizontally in pipelines.

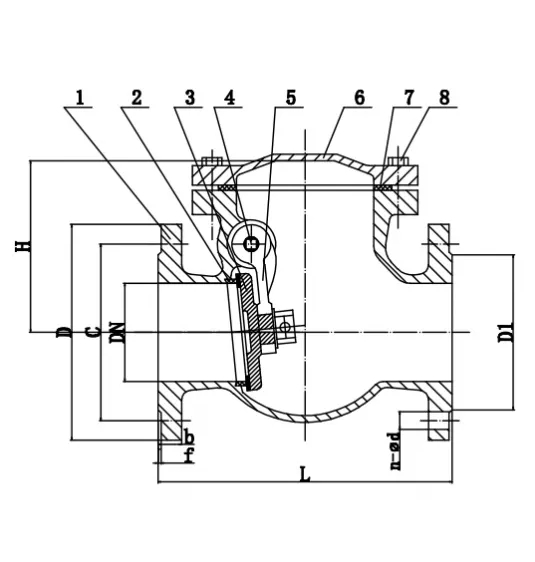

Part & Materials

| No | Part | Material |

| 1 | Body | Ductile Iron GGG50 |

| 2 | Seat | Brass |

| 3 | Disc | GGG50+Brass /EPDM |

| 4 | Shafe | SS420 |

| 5 | Rocker | Ductile Iron GGG50 |

| 6 | Bonnet | Ductile Iron GGG50 |

| 7 | Seal Gasket | Metallic Gasket / Rubber |

| 8 | Bolts | A2-70 |

Dimensions(mm)

| DN | L | D | C | B | n-d | b | f | H | |||||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||

| DN50 | 200 | 165 | 125 | 99 | 4-19 | 19 | 3 | 130 | |||||

| DN65 | 240 | 185 | 145 | 119 | 4-19 | 19 | 3 | 150 | |||||

| DN80 | 260 | 200 | 160 | 133 | 8-19 | 19 | 3 | 155 | |||||

| DN100 | 300 | 220 | 180 | 154 | 8-19 | 19 | 3 | 165 | |||||

| DN125 | 350 | 250 | 210 | 184 | 8-19 | 19 | 3 | 185 | |||||

| DN150 | 400 | 285 | 240 | 210 | 8-23 | 19 | 3 | 205 | |||||

| DN200 | 500 | 340 | 295 | 265 | 8-23 | 12-23 | 20 | 3 | 250 | ||||

| DN250 | 600 | 405 | 350 | 355 | 319 | 12-23 | 12-28 | 22 | 3 | 310 | |||

| DN300 | 700 | 460 | 400 | 410 | 370 | 12-23 | 12-28 | 24.5 | 4 | 360 | |||

| DN350 | 800 | 520 | 460 | 470 | 429 | 16-23 | 16-28 | 26.5 | 4 | 405 | |||

| DN400 | 900 | 580 | 515 | 525 | 480 | 16-28 | 16-31 | 28 | 4 | 470 | |||

Technical Data

| No | Description | Specification |

| 1 | Nominal Dia | DN50-DN400 |

| 2 | Nominal Pressure | PN10&PN16 |

| 3 | Valve Design Standard | DIN3202 F6 |

| 4 | Face to Face Standard | EN558&ISO5752 Series-48 |

| 5 | Flange Standard Conformity | DIN2533 |

| 6 | Testing Standard | DIN3230 |

| 7 | Expoxy Coating | Epoxy powder coating with minimum thickness of 250 microns inside and outside. |

| 8 | Testing Pressure | |

| Shell Test | PN*1.5Times | |

| Sealing Test | PN*1.1Times | |

| 9 | Working Temperature(Max) | 120℃ |