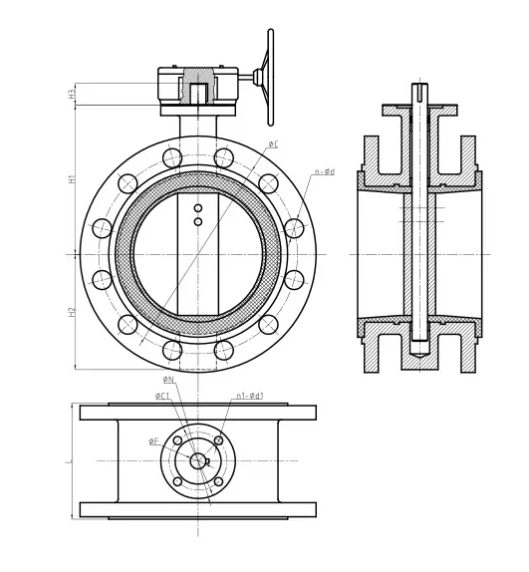

Flange Type Turbine Butterfly Valve

Related recommendations : Wafer Type Turbine Butterfly Valve | Clamping Type Manual Butterfly Valve | Flange Expansion Turbine Butterfly Valve

CONTACT

Product details

The flange type turbine butterfly valve generally adopts a three eccentric multi-level metal hard sealing structure, and is used in industrial pipelines such as metallurgy, power, petrochemical, water supply and drainage, and municipal construction where the medium temperature is ≤ 425 ℃. It is used for regulating flow and carrying fluid.

Part & Materials

| No | Part | Material |

| 1 | Body | Ductile Iron GGG50+EPDM |

| 2 | Shaft | SS410 |

| 3 | Disc | DI/CF8/CF8M |

| 4 | Pin | SS304 |

| 5 | Sleeve | Polymer |

| 6 | Sealing | EPDM/NBR |

| 7 | Gear Box | Ductile Iron GGG50 |

Dimensions(mm)

| DN | L | H1 | H2 | H3 | Flange Type | N | C1 | n1-d1 | DIN2501PN10 | DIN2501 PN16 | F | ||

| C | n-d | C | n-d | ||||||||||

| DN50 | 108 | 110 | 80 | 29 | F05 | 65 | 50 | 4-8 | 125 | 4-18 | 125 | 4-18 | 12.6 |

| DN65 | 112 | 134 | 80 | 29 | F05 | 65 | 50 | 4-8 | 145 | 4-18 | 145 | 4-18 | 12.6 |

| DN80 | 114 | 131 | 95 | 29 | F05 | 65 | 50 | 4-8 | 160 | 8-18 | 160 | 8-18 | 12.6 |

| DN100 | 127 | 150 | 114 | 29 | F07 | 90 | 70 | 4-10 | 180 | 8-18 | 180 | 8-18 | 15.77 |

| DN125 | 140 | 170 | 113 | 29 | F07 | 90 | 70 | 4-10 | 210 | 8-18 | 210 | 8-18 | 18.92 |

| DN150 | 140 | 180 | 139 | 29 | F07 | 90 | 70 | 4-10 | 240 | 8-22 | 240 | 8-22 | 18.92 |

| DN200 | 152 | 210 | 175 | 35 | F10 | 125 | 102 | 4-12 | 295 | 8-22 | 295 | 12-22 | 22.1 |

| DN250 | 165 | 246 | 204 | 35 | F10 | 125 | 102 | 4-12 | 350 | 12-22 | 355 | 12-26 | 28.45 |

| DN300 | 178 | 276 | 246 | 35 | F10 | 125 | 102 | 4-12 | 400 | 12-22 | 410 | 12-26 | 31.6 |

| DN350 | 190 | 312 | 253 | 45 | F10 | 125 | 102 | 4-12 | 460 | 16-22 | 470 |  16-26 16-26 | 31.6 |

| DN400 | 216 | 343 | 282 | 51.2 | F14 | 175 | 140 | 4-18 | 515 | 16-26 | 525 | 16-30 | 33.15 |

| DN450 | 222 | 380 | 323 | 51.2 | F14 | 175 | 140 | 4-18 | 565 | 20-26 | 585 | 20-30 | 38 |

| DN500 | 229 | 436 | 352 | 64.2 | F14 | 175 | 140 | 4-18 | 620 | 20-26 | 650 | 20-33 | 41.15 |

| DN600 | 267 | 515 | 415 | 70.2 | F16 | 210 | 165 | 4-22 | 725 | 20-30 | 770 | 20-36 | 50.65 |

| DN700 | 292 | 561 | 481 | 66 | F25 | 300 | 254 | 8-18 | 840 | 24-30 | 840 | 24-36 | 63 |

| DN800 | 318 | 622 | 532 | 66 | F25 | 300 | 254 | 8-18 | 950 | 24-33 | 950 | 24-39 | 63 |

| DN900 | 330 | 690 | 555 | 118 | F25 | 300 | 254 | 8-18 | 1050 | 28-33 | 1050 | 28-39 | 75 |

| DN1000 | 410 | 727 | 674 | 142 | F25 | 300 | 254 | 8-18 | 1160 | 28-36 | 1170 | 28-42 | 85 |

Technical Data

| No | Description | Specification |

| 1 | Nominal Dia | DN50-DN1200 |

| 2 | Nominal Pressure | PN10&PN16 |

| 3 | Valve Design Standard | EN593 |

| 4 | Face to Face Standard | EN558&ISO5752 Series-13 |

| 5 | Flange Standard Conformity | DIN2501/EN1092 |

| 6 | Expoxy Coating | Epoxy powder coating with minimum thickness of 250 microns inside and outside. |

| 7 | Working Temperature(Max) | 120℃ |